A Legacy of Excellence: The Story of GIFFIN

As GIFFIN celebrates its 75th anniversary, we reflect with deep reverence on the legacy we’ve built. Our company embodies a culture rooted in family values, integrity, and continuous innovation. Looking ahead, we draw inspiration from our journey and remain dedicated to providing the highest quality custom finishing solutions to our customers. From our humble beginnings as a small sheet metal shop, to becoming a renowned industry leader, our history is a testament to the determination of three generations.

Humble Beginnings:

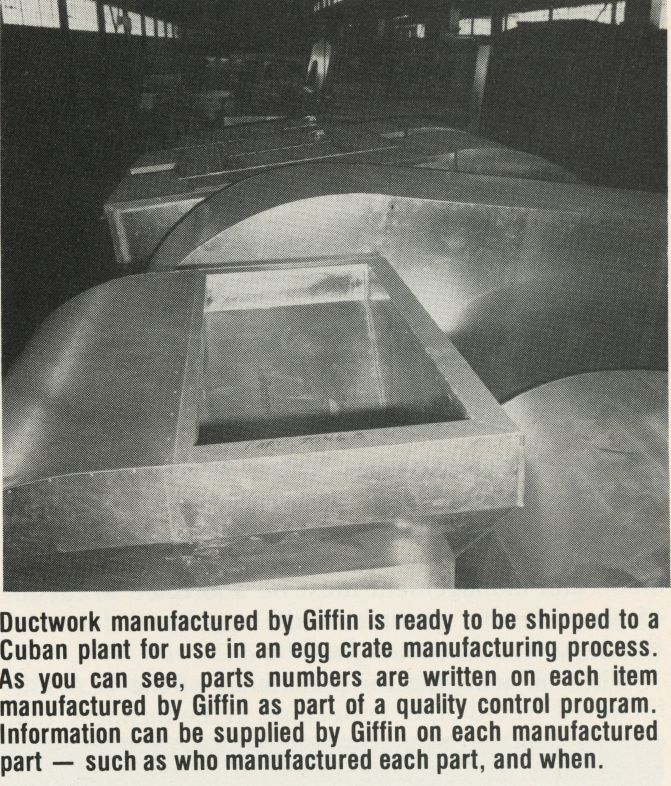

GIFFIN Sheet Metals was founded on September 29th, 1949, by Donald P. Giffin SR. in Toronto, Ontario. The business started with a focus on ventilation ductwork in the commercial HVAC industry. GIFFIN Sheet Metal’s first professional project was Toronto’s City Hall ventilation and flashings.

The company's only asset in the early days was my ambition and determination to succeed.

-D.P. Giffin Sr.

Building a Reputation in HVAC

It didn’t take long for GIFFIN Sheet Metals to establish a strong reputation, thanks to their unwavering commitment to quality, safety, and customer satisfaction. In the 1950s, the company focused on serving hospitals, universities, and factories with a specialization in commercial HVAC systems.

Driven by a relentless will to succeed and an unflinching belief that “One can carve a career out of any endeavor, if one truly tries.

-D.P. Giffin SR.

A Focus on Diversification and Innovation

In the 1960s, GIFFIN Sheet Metals grew exponentially by focusing on expanding into new markets and innovating based on industry standards at the time. To accommodate their growing operational needs, the company moved to a new manufacturing plant on Bridgeland Avenue in Toronto. Ensconced in their new digs, GIFFIN grew with a strategic shift toward the industrial sector and automotive market.

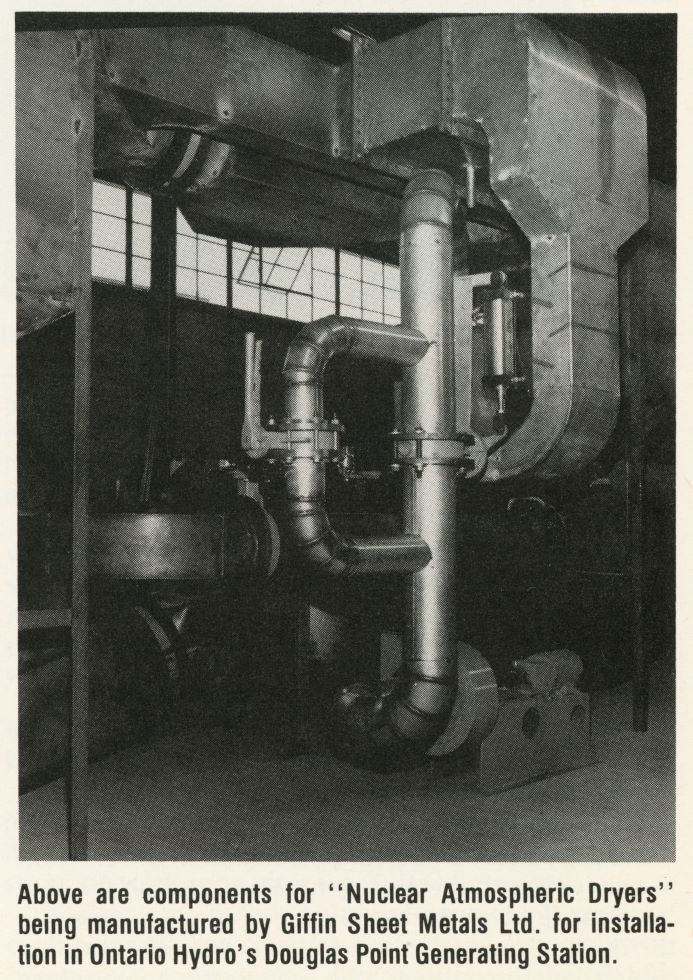

During this time, GIFFIN became a pioneer in the nuclear energy sector, contributing to the Rolphton nuclear power generation station, Canada’s first nuclear demonstration plant. This growth brought further work involving the CANDU reactors for which GIFFIN was the only Canadian manufacturing facility certified for fabrication and installation. This project showcased their ability to adapt and excel in highly specialized fields.

This advancement led them to more projects in stainless steel manufacturing, including notable work for Ford’s Oakville and St. Thomas plants. These projects further established GIFFIN Sheet Metals as an industry leader and innovator.

We are constructors. We live by construction. Each and every one of us must be constructive.

-D.P. Giffin SR.

A New Era in Automotive Industry Expansion

The 1970s were a time when GIFFIN Sheet Metals achieved major breakthroughs in the automotive industry. This solidified their reputation even further, as they got to work with large OEMs like GM and Ford. During this time, the company developed advanced systems for automotive surface finishing. Overall, this decade marked a pivotal expansion for the company with the introduction of GIFFIN Contractors in Toronto; and the establishment of GIFFIN Inc. in the United States, led by second generation, Donald J.P. GIFFIN.

A strategic expansion designed to propel the GIFFIN family tree further into the automotive and OEM industries through the addition of paint finishing, metal treatment, energy reduction, pollution control, air handling, and project management solutions. GIFFIN cemented their name as key player in large scale manufacturing, with heavy focus on supporting the automotive industry’s specialty fabrication needs, while servicing other industries.

I have spent my entire life in construction work - coast to coast - from Canada, USA, to the Artic Circle, during my 43yrs of involvement I have seen the industry undergo tremendous changes.

-D.P. GIFFIN SR.

Entry Into the US Market

GIFFIN Inc. established its presence in the United States in December 1980, setting up operations in Southfield, MI. This strategic move proved beneficial very quickly, with GIFFIN securing its first large automotive contract in the USA at GM Framingham. In 1985, the company further solidified its status by relocating to a facility in Farmington, MI, which featured an 80,000 sq. ft. fabrication shop. This enabled them to meet the increasing demands of the market and continue their legacy of excellence and innovation.

Diversifying continued into new arenas with the manufacturing of ventilation and dust collection systems for the food and pulp & paper sectors and odor control systems for wastewater treatment plants. Whether operating solely or collaborating with another division within the GIFFIN Family Tree, GIFFIN has always strived to generate innovative and cost-saving measures for all clients.

Tremendous step forward! GIFFIN Inc’s expansion into the US markets has led to immediate success with Detroit’s Big Three through several successful turnkey projects.

-D. J.P.GIFFIN

Well-Deserved Industry Recognition

In the 1990s, GIFFIN focused on consolidation and earned significant recognition for its efforts. In 1993, the company secured a major contract for a program at Ford St. Louis, further solidifying their reputation in the automotive sector.

Continued innovation led GIFFIN to the development and installation of their first scrubber within the new prime spraybooths at GM Arlington. This decade continued to spark profound growth and industry recognition, GIFFIN had achieved QS 9000, TE-Supplement, and R&M compliance, based on an independent audit.

We can build anything, any size, anywhere

-D. J.P. GIFFIN

New Growth and Technological Advancements

In the 2000s, GIFFIN embraced technological advancements and global expansion, securing major contracts that demonstrated their growing influence in the industry. In 2000, the company established a Sales, Engineering, Estimating, and Project Management office in Mexico, and received the prestigious Q1 Award from Ford Motor Company.

In 2005, GM selected GIFFIN for a new Greenfield paint shop in San Luis Potosi, Mexico. Building on this success, Boeing chose GIFFIN in 2008 to develop a Greenfield Metal Treatment Facility in Gresham, Oregon. This project, which achieved LEED Gold Accreditation, further cemented GIFFIN’s reputation.

Everyone in the industry now knows how much we stand for both sustainability and innovation.

-D. J. P. GIFFIN

Continued Growth and Innovation

In 2010, GIFFIN Inc. relocated its headquarters to Auburn Hills, MI, doubling its office space and manufacturing capacity. This move inspired a decade of significant growth and innovation. During this time, the company secured a major aerospace program from Rolls Royce for two turnkey Jet Turbine Disc Metal Treatment Lines.

GIFFIN continued to land major contracts throughout this decade. In 2012, they secured the Sterling Heights Assembly Plant UF Paint Shop program for Chrysler, followed by a Topcoat Paint Shop for Continental Structural Plastics in 2014. In 2015 and 2016, orders for advanced paint shop technologies for Kenworth, SMR, and Magna Mirrors in Mexico further established their industry leadership.

The company’s innovation was recognized in 2017 when it received the PACE Award for their ELITE wet scrubbing technology. GIFFIN maintained its momentum with a turnkey Topcoat Paint Shop for Continental Structural Plastics in 2018 and new paint shop projects for Stellantis in Detroit and Warren, MI in 2019. They also completed a new 100,000-square-foot manufacturing center at their Auburn Hills campus and were honored with the 2019 Supplier of the Year award from FCA-Stellantis.

GIFFIN's ability to continuously execute larger and larger automotive programs, while fostering a strategic diversification endeavor into the aerospace, heavy truck, and tier supplier sectors, further solidifies the strength of our leadership, and overall team.

-D. Richard Giffin

Responding to Global Challenges

In 2020, GIFFIN partnered with Ford Motor Co. in a relief effort to fight the COVID-19 pandemic, with Ford Motor Co. Chairman Bill Ford visiting the new cleanroom facility constructed to manufacture critical ventilators at significant scale.

Today, GIFFIN continues to overcome obstacles, drive industry trends, and expand their quality and expertise in every way possible. In the same way that our history has pointed to rapid innovation and expansion, so will the future. This is just the beginning of a journey that will continue to grow and evolve for decades to come.

GIFFIN's ability to construct five paint shops at the same time, during a global pandemic, while delivering them to our customers on time, on budget, with superior quality, is a testament to our teams resilience, and overall commitment to our customers.

-D. Richard Giffin